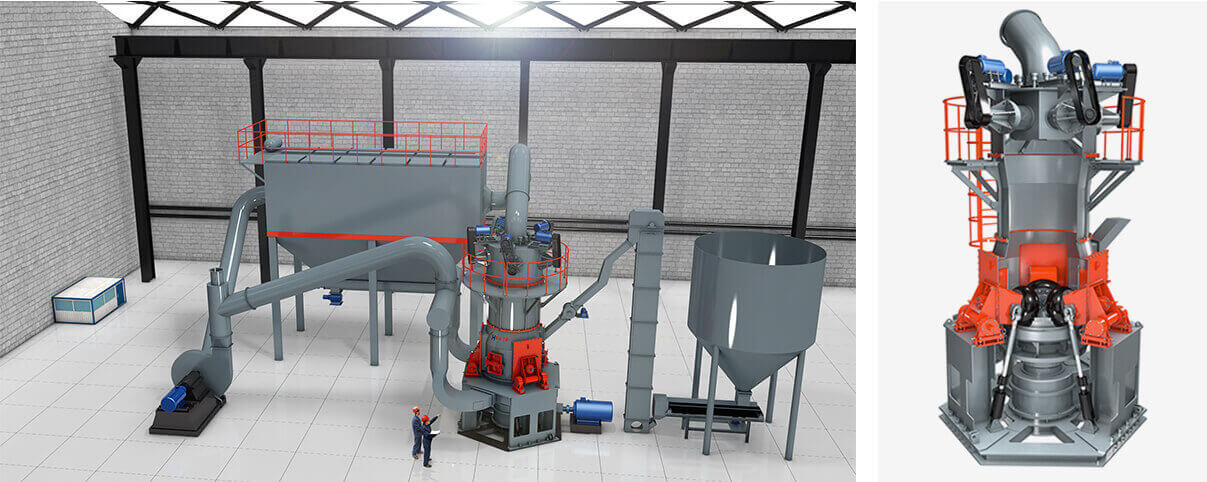

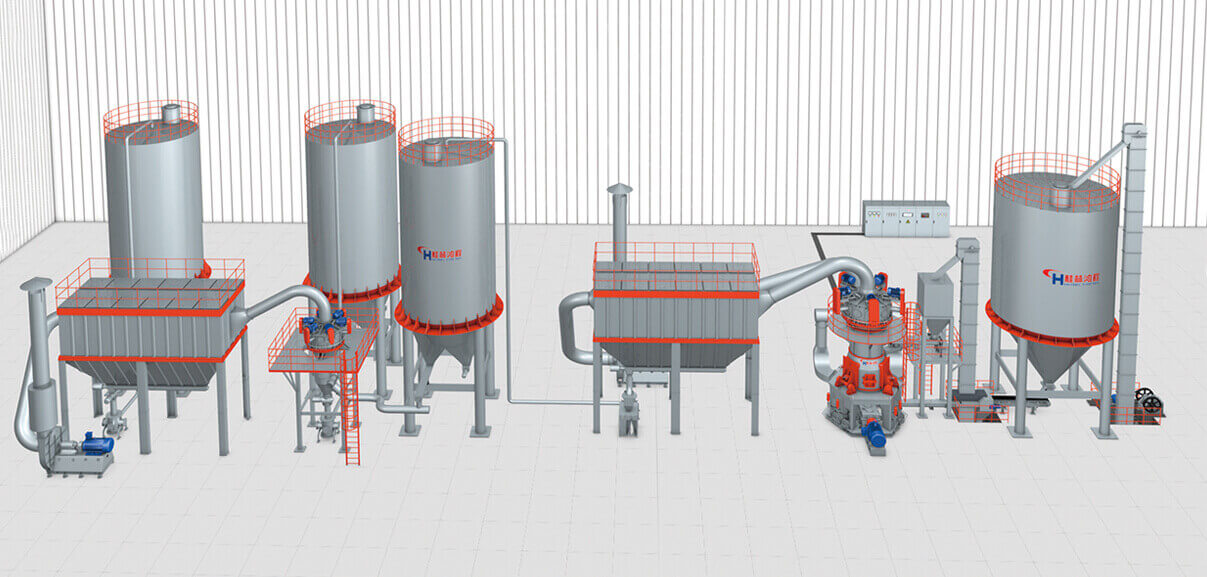

Ukusebenza kahle kokugaya nokonga amandla. Umthamo weyunithi eyodwa ungafinyelela ku-40t/h. Ukusebenzisa izihlungi zekhanda elilodwa neliningi, asikho isidingo sokusebenzisa ukuhlukaniswa komoya wesibili kanye nokuhlukaniswa, futhi kungonga ukusetshenziswa kwamandla okungu-30% -50% kunezigayo ezivamile.

qonda

UDINGA ISIXAZULULO?Ukuze uthole ulwazi olwengeziwe ngomshini wokugaya noma isicelo sekhotheshini sicela uxhumane nathi.

UphenyoXhumana nathi

Siyakwamukela ku-Guilin HongchengI-Guilin HongCheng Mining Equipment Manufacture Co., Ltd.

- Ucingo:86-15107733434

- Ikheli:Yangtang Shanshui Industrial Park, Xicheng Economic Development Zone, Guilin City, Guangxi Province, China

- I-imeyili:hcmkt@hcmilling.com

- Ucingo:+91 97125 28918

- I-imeyili:hgvala@gmail.com

Umqondisi wokumaketha waseNdiya

© Ilungelo Lokushicilela - 2010-2025: Wonke Amalungelo Agodliwe.Imikhiqizo Eshisayo - Imephu yesayithi

I-Petroleum Coke Vertical Roller Mill, Isigayo Sokugaya Esihle Kakhulu, Ukugaya Amalahle, Isigayo Esihle Kakhulu, Isigayo Sokugaya, Umshini Wokugaya Upende Wempuphu Ovela Kumhlinzeki WaseShayina,

I-Petroleum Coke Vertical Roller Mill, Isigayo Sokugaya Esihle Kakhulu, Ukugaya Amalahle, Isigayo Esihle Kakhulu, Isigayo Sokugaya, Umshini Wokugaya Upende Wempuphu Ovela Kumhlinzeki WaseShayina,