Isingeniso ku-Dolomite

I-Dolomite uhlobo lweminerali ye-carbonate, okuhlanganisa i-ferroan-dolomite kanye ne-mangan-dolomite. I-Dolomite iyisakhi esikhulu samaminerali se-dolomite limestone. I-dolomite emsulwa imhlophe, eminye ingaba mpunga uma inensimbi.

Ukusetshenziswa kwe-dolomite

I-Dolomite ingasetshenziswa ezintweni zokwakha, i-ceramic, ingilazi, izinto eziphikisayo, amakhemikhali, ezolimo, ukuvikelwa kwemvelo kanye nezinkambu zokonga amandla. I-Dolomite ingasetshenziswa njengezinto eziyisisekelo eziphikisayo, i-blast furnace flux, umanyolo we-calcium magnesium phosphate, kanye nezinto zemboni yesamente nengilazi.

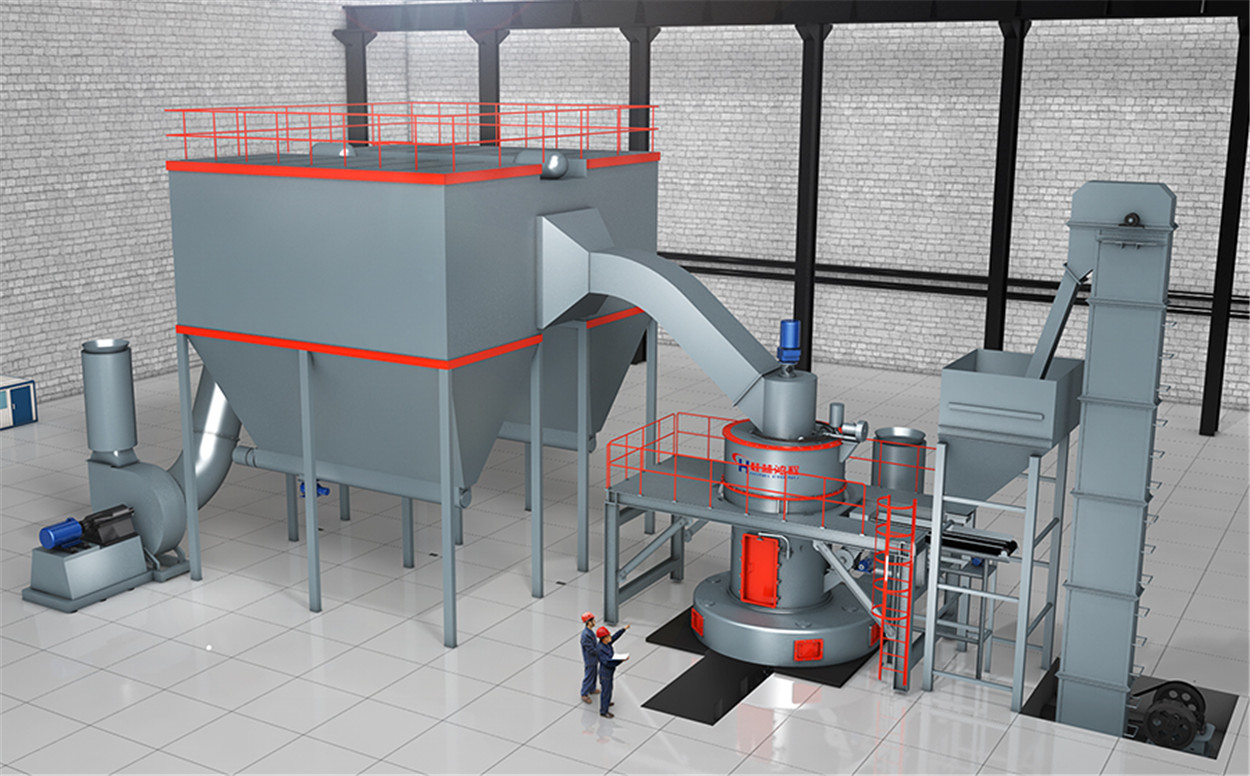

Inqubo yokugaya i-Dolomite

Ukuhlaziywa kwezingxenye zezinto zokusetshenziswa ze-dolomite

| I-CaO | I-MgO | I-CO2 |

| 30.4% | 21.9% | 47.7% |

Qaphela: ivame ukuqukethe ukungcola okufana ne-silicon, i-aluminium, insimbi kanye ne-titanium

Uhlelo lokukhetha imodeli yomshini wokwenza impuphu ye-dolomite

| Imininingwane yomkhiqizo | Impuphu ecolekile (i-mesh engu-80-400) | Ukucubungula okujulile okuhle kakhulu (400-1250 mesh) | Impuphu encane (1250-3250 mesh) |

| Imodeli | Umshini wokugaya iRaymond, umshini wokugaya oqondile | Isigayo esihle kakhulu, isigayo esiqondile esihle kakhulu | |

*Qaphela: khetha umshini oyinhloko ngokuya ngezidingo zokukhipha kanye nokuqina

Ukuhlaziywa kwamamodeli okugaya

1. Umshini Wokugaya Uchungechunge lwe-HC: izindleko zokutshalwa kwezimali eziphansi, umthamo ophezulu, ukusetshenziswa kwamandla okuphansi, ukusebenza okuzinzile, umsindo ophansi. Okubi: umthamo owodwa ophansi, hhayi imishini emikhulu.

2. I-HLM Vertical Mill: imishini emikhulu, umthamo ophezulu, ukusebenza okuzinzile. Okubi: izindleko zokutshalwa kwezimali eziphakeme.

3. I-HCH Ultra-fine Mill: izindleko zokutshalwa kwezimali eziphansi, ukusetshenziswa kwamandla okuphansi, izindleko eziphansi. Ububi: umthamo ophansi, amasethi amaningi emishini ayadingeka ukwakha umugqa wokukhiqiza.

4. I-HLMX Ultra-fine Vertical Mill: ikwazi ukukhiqiza i-1250 mesh ultra-fine powder, ngemva kokuhlonyiswa ngohlelo lokuhlukanisa amazinga amaningi, i-2500 mesh micro powder ingakhiqizwa. Imishini inomthamo ophezulu, inesimo esihle sokukhiqiza, iyisikhungo esifanele sokucubungula i-powder esezingeni eliphezulu. Ububi: izindleko zokutshala imali eziphakeme.

Isigaba I: Ukuchotshozwa kwezinto zokusetshenziswa

Izinto ezinkulu ze-dolomite zichotshozwa yi-crusher kuze kube yilapho ukuphakelwa kuncane khona (15mm-50mm) okungangena emshinini wokugaya.

Isigaba II: Ukugaya

Izinto ezincane ze-dolomite ezichotshoziwe zithunyelwa endaweni yokugcina izinto nge-elevator, bese zithunyelwa ekamelweni lokugaya lesitsha ngokulinganayo nangobuningi yi-feeder ukuze zigaywe.

Isigaba III: Ukuhlukaniswa

Izinto ezigayiwe zilinganiswa ngohlelo lokulinganisa, kanti impuphu engafaneleki ilinganiswa ngohlelo lokuhlukanisa bese ibuyiselwa emshinini oyinhloko ukuze igaywe kabusha.

Isigaba V: Ukuqoqwa kwemikhiqizo eqediwe

Impuphu evumelana nobuncane igeleza ngepayipi kanye negesi bese ingena eqoqweni lokuqoqa uthuli ukuze ihlukaniswe futhi iqoqwe. Impuphu eqoqwe ithunyelwa esigungwini somkhiqizo oqediwe ngedivayisi yokudlulisa ngembobo yokukhipha, bese ipakishwa yithangi lempuphu noma i-automatic packer.

Izibonelo zokusetshenziswa kokucubungula i-dolomite powder

Umshini wokugaya i-Dolomite: umshini wokugaya oqondile, umshini wokugaya i-Raymond, umshini wokugaya omuhle kakhulu

Izinto zokucubungula: i-Dolomite

Ubunono: 325 mesh D97

Umthamo: 8-10t / h

Ukucushwa kwemishini: Isethi eyi-1 ye-HC1300

Isethi ephelele yemishini yaseHongcheng inenqubo encane, indawo encane yephansi futhi isindisa izindleko zesitshalo. Lonke uhlelo lulawulwa ngokuzenzakalela ngokuphelele, futhi uhlelo lokuqapha olukude lungangezwa. Izisebenzi zidinga kuphela ukusebenza egumbini lokulawula eliphakathi, okulula ukulisebenzisa futhi konga izindleko zabasebenzi. Ukusebenza komshini wokugaya nakho kuzinzile futhi umphumela ufinyelela okulindelekile. Konke ukuklama, isiqondiso sokufaka kanye nokuqaliswa komsebenzi wonke kumahhala. Selokhu kusetshenziswa umshini wokugaya waseHongcheng, umkhiqizo wethu kanye nokusebenza kahle kwethu kuthuthukisiwe, futhi sanelisekile kakhulu.

Isikhathi sokuthunyelwe: Okthoba-22-2021